Unlocking the Benefits of Lean Manufacturing

Ready to unlock the biggest wins from lean manufacturing? Start by focusing on three key goals: achieving significant cost savings, delivering impeccable product quality, and getting your products into customers' hands faster than ever before. The path to achieving this is simple: meticulously hunt down and eliminate waste from every single corner of your production process.

The Power of Lean: A Guide to Transformation

Reshape your business from the ground up—not with a huge cash injection, but with a profound shift in how you think and work. That's the real power of lean manufacturing. It’s far more than just a set of tools for the factory floor; it’s a philosophy dedicated to relentlessly chasing perfection by getting rid of everything that doesn't add genuine value for your customer.

This guide is your roadmap. We'll walk you through the practical steps to build a more nimble, resilient, and successful operation. Let's peel back the layers of the core principles and arm you with actionable insights you can implement starting right now.

Your Path to Operational Excellence

At its core, lean is about a simple mission: create more value for your customers using fewer resources. To put this into action, adopt the mindset of a master chef refining a signature dish—carefully remove every distracting ingredient and wasted movement until only perfection remains. This intense focus sharpens every part of your business. Make this relentless pursuit of 'better' a part of your company's DNA through a commitment to continuous improvement in manufacturing.

For a design-first brand like Griseo Interior, this isn’t about sacrificing artistry for assembly-line speed. It's about elevating the made-to-order experience by closing the gap between a customer's dream and their finished piece with absolute precision and efficiency.

Here are the tangible rewards you can expect when you implement this approach:

- Boost Financial Strength: When you slash waste, you directly cut operating costs. Reinvest that freed-up capital into what truly matters—your designs, innovation, and growth.

- Create Happier Customers: Deliver products faster and with superior quality to build deep trust and fierce loyalty. Turn one-time buyers into passionate advocates for your brand.

- Empower Your Teams: Foster a culture where every team member is encouraged to spot problems and propose solutions. This boosts morale, engagement, and a shared sense of ownership.

- Build a Sustainable Future: Implement efficient processes that naturally use fewer materials and less energy, perfectly aligning your business with the values of today’s eco-conscious customer.

"Lean is not a project with a defined end; it is a way of thinking and acting for an entire organization. It's about building a culture that constantly strives for a better way to work."

Slashing Costs by Chasing Down Hidden Waste

Let’s focus on the most powerful, immediate action you can take to boost your bottom line: a deliberate hunt for the hidden costs draining your business. These costs are often disguised as "the way we’ve always done things."

Treat your workshop like a master chef's kitchen. Trim every ounce of fat. Every wasted motion, extra piece of material, and moment of downtime is an opportunity for huge savings. When you start viewing your operations through this lens, small, consistent changes begin to stack up into major financial wins.

This isn’t just theory. Companies that truly commit to lean often see 25-30% reductions in their overall manufacturing costs. This is capital you can immediately reinvest in better materials, new designs, or growing your team.

Hunting the Eight Wastes in Your Workshop

So, where do you start? The first step is to know what to look for. Lean pinpoints eight specific types of waste—activities that burn resources but add zero value from your customer’s perspective. Your job is to spot them and eliminate them for good.

- Defects: Every piece that needs rework costs you time, materials, and labor. Implement quality checks at each step, not just at the end.

- Overproduction: Making more than you have orders for is a classic cash trap. Shift to a made-to-order model like ours at Griseo Interior to solve this.

- Waiting: Identify idle time—whether it's a person, a machine, or a product—and find the bottleneck causing the delay.

- Non-Utilized Talent: Actively solicit ideas from your front-line team. Create a simple system for them to submit suggestions for improvement.

- Transportation: Redesign your floor layout to minimize the distance materials or products have to travel between stations.

- Inventory: Reduce excess raw materials and finished goods. Use a 'just-in-time' (JIT) approach to order supplies only as you need them.

- Motion: Observe your team at work. Can you reorganize a workstation so that all necessary tools are within arm's reach? Eliminate unnecessary steps.

- Extra-Processing: Ask yourself if a step adds value the customer is willing to pay for. Stop polishing the back of a cabinet no one will ever see.

Making Waste Impossible to Ignore

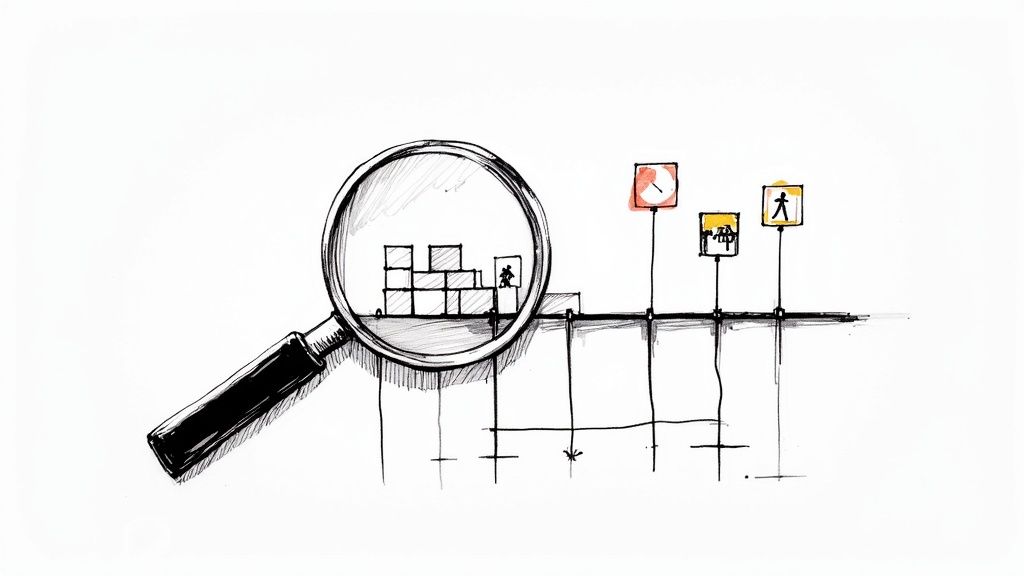

The best way to get started is by conducting a ‘waste walk.’ This isn't a boardroom exercise; it’s a hands-on walk-through of your entire process, from order intake to final shipping. Your only job is to consciously look for those eight wastes.

Map your entire workflow on a whiteboard or with sticky notes. This simple act makes the invisible visible, putting a spotlight on bottlenecks and inefficiencies that are impossible to ignore.

When waste is visible, it becomes an invitation for innovation. Each inefficiency you spot is not a failure, but a golden opportunity to make your process stronger, more efficient, and more profitable.

Chasing down waste has another powerful side effect: it naturally creates a more sustainable operation. Using fewer materials and less energy is not only good for your wallet, but it’s also great for the planet. For more inspiration on this, dive into our guide on https://griseointerior.com/blogs/blog/sustainable-supply-chain-practices.

Even small, targeted improvements can make a world of difference. For instance, optimizing your final steps with the right packaging machinery to boost efficiency can help eliminate a common bottleneck. It's these focused actions that, when combined, slash costs and build a truly resilient, competitive business.

Building Unbeatable Quality into Your Process

Stop fighting fires and start preventing defects from ever happening in the first place. Use lean manufacturing to shift quality control from a reactive, last-minute inspection to a proactive, continuous part of your creation process. Build quality into every single step, not just hoping to catch mistakes at the end.

This simple shift flips traditional manufacturing on its head. Instead of relying on a single inspector, empower every person on your team to become a champion of quality. This fosters a powerful culture of pride and excellence, turning superior craftsmanship into your most authentic marketing tool.

Make Mistakes Nearly Impossible

One of the most powerful tools in the lean toolkit is Poka-Yoke, a Japanese term that translates to "error-proofing." The goal is to design your process in a way that makes mistakes incredibly difficult, if not impossible, to make.

Think of a modern USB-C cable—you literally can't plug it in wrong. That’s Poka-Yoke. Here's how to bring this thinking into your own workshop:

- Create Custom Jigs: Build guides or templates that hold a piece in the exact right position for drilling or cutting, eliminating any chance of misalignment.

- Implement Color-Coded Systems: Use colors to match parts with their corresponding tools, making it immediately obvious if someone grabs the wrong component.

- Use Simple Checklists: Mount visual checklists at each workstation to confirm all steps are completed correctly before a piece moves to the next stage.

These solutions are often incredibly simple and low-cost, yet they're far more effective than relying on memory or vigilance. They build a safety net that catches potential errors before they become costly defects.

Digging for the Root Cause

When a defect does sneak through, don't just fix it and move on. Go deeper with a simple but powerful technique called the ‘5 Whys.’ By repeatedly asking "Why?" you can peel back the layers of an issue to find its true origin, rather than just patching up a symptom.

By asking "Why?" five times, you can trace the entire chain of events that led to a failure. This ensures you're not just patching a leak but fixing the pipe itself, preventing the same issue from ever happening again.

This deeper level of problem-solving is the bedrock of building unshakeable quality. It’s a key reason why companies that truly embrace lean principles often see their defect rates plummet by up to 80%. By focusing on root causes, error-proofing your systems, and standardizing your best work, you create a process that produces excellence by design. You can explore more about how lean continues to shape modern workshops with these insights on AirAcad.com.

Accelerating Delivery and Delighting Customers

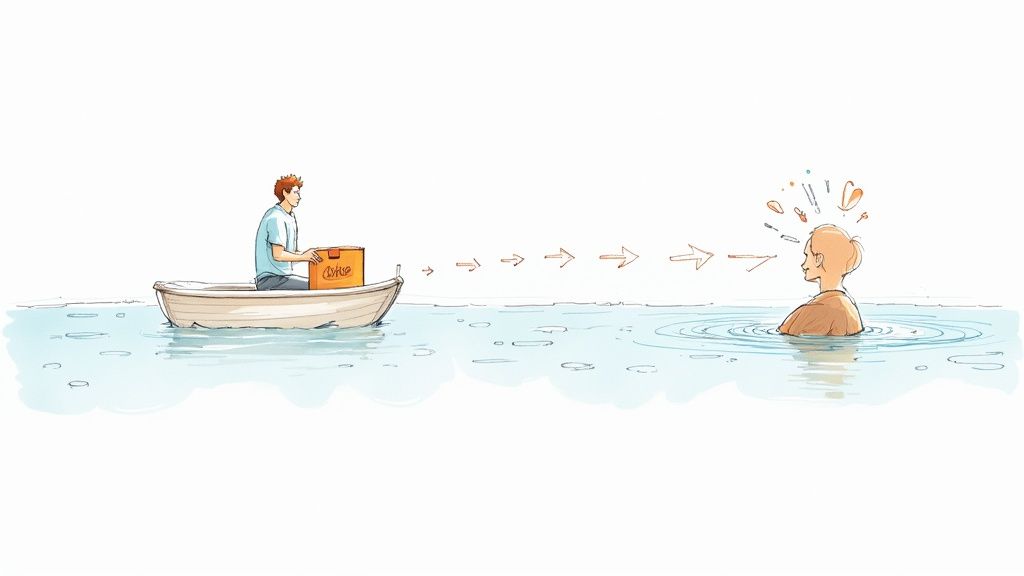

In a world that wants everything yesterday, speed is a superpower. Closing the gap between the moment a customer clicks "buy" and the moment they unbox their order is one of the most powerful outcomes of a lean mindset. Take action to turn your production process into a genuine competitive edge that builds unshakable loyalty.

Picture your entire production process as a river. Obstructions like bottlenecks, delays, and queues clog the channel, turning a powerful current into a stagnant pond. Lean is the art of methodically removing every single one of those obstructions. When you eliminate waste like waiting, unnecessary movement, and rework, you inject pure speed into your entire operation.

Visualizing Your Path to Speed

The first step toward creating seamless flow is to see your process with completely fresh eyes. Use a simple but profound tool for this: value stream mapping. This isn't complex software; it's a hands-on exercise where you and your team literally draw out every single action, from the initial order to the final delivery.

By visualizing the entire journey, you can pinpoint exactly where time is being lost. You might discover a piece sits for days waiting for a specific finish, or that your team wastes hours each week just hunting for materials. These are the dams in your river.

Once you can see the bottlenecks, break them down with these direct actions:

- Organize Workstations: Arrange tools and materials logically, following the natural sequence of work to create an intuitive flow and minimize movement.

- Establish a 'Pull' System: Instead of pushing work to the next stage, let that stage "pull" it when they have capacity. This stops work-in-progress from piling up.

- Reduce Batch Sizes: Work on smaller batches or even single pieces. This makes you far more flexible and gets individual items finished and out the door much faster.

This systematic approach has been shown to slash lead times. Companies that truly embrace lean principles often see reductions of 70-90%, a benchmark set by pioneers like Toyota who famously cut their production cycles from weeks to just days. To learn more about the modern strategies behind these results, check out the insights at Gocious.com.

The Ripple Effect of Faster Delivery

Speeding up your lead time does so much more than just keep customers happy. It sets off a cascade of positive effects that ripple through your entire business. A faster turnaround means you get paid sooner, which dramatically improves cash flow and gives you far more financial breathing room.

"A shorter lead time shrinks the 'order-to-cash' cycle, injecting vital liquidity into your business. It allows you to be more agile, responding instantly to new trends and customer demands without being weighed down by slow processes."

This kind of responsiveness is absolutely crucial for businesses built on personalization and quality. For artisan brands that live and die by customer delight, like those offering made-to-order furniture, a streamlined process is the secret to delivering on a promise of bespoke excellence without frustrating delays.

When you focus on flow, you build an operation that isn't just efficient—it's exceptionally responsive and wired to serve your customer.

Fostering Sustainability and Operational Flexibility

Beyond wins in your budget and quality control, lean manufacturing champions two critical values: sustainability and adaptability. These aren't just buzzwords; they are practical goals that forge a deeper connection with your customers and build a business that’s resilient enough to thrive for the long haul.

At its core, lean is a relentless quest to eliminate waste. This mission, by its very nature, makes your entire operation more eco-friendly. Every offcut you don't produce, every kilowatt of energy you don't use, and every unnecessary shipment you avoid is a tangible win for the environment. It’s an authentic story that customers not only appreciate but actively seek out.

Building a Greener Footprint by Design

A lean process is a green process. The link is direct and powerful. When your primary focus is creating incredible value with the fewest possible resources, you automatically shrink your environmental footprint. It’s not a separate "green initiative"—it's a natural outcome of working smarter.

Take these steps to boost your company’s eco-credentials:

- Reduce Material Waste: Focus on precision and getting it right the first time to send less raw material to the landfill.

- Lower Energy Consumption: Design efficient workflows with minimal idle time so your equipment only runs when it’s creating value.

- Optimize Transportation: Implement a smart facility layout and a dialed-in supply chain to cut down on the fuel and emissions needed to move materials.

This drive for efficiency creates a powerful environmental narrative. The U.S. Environmental Protection Agency has even noted that lean practices directly cut emissions, water usage, and hazardous waste. It helps companies hit their sustainability targets without launching separate, expensive programs.

We dive deeper into this in our guide on sustainable manufacturing practices, which is full of ideas to inspire your own journey.

Gaining the Superpower of Flexibility

Here’s where it gets really exciting. Lean gives you the incredible gift of operational flexibility. Old-school manufacturing is built on massive, repetitive production runs, which makes it slow to change direction. Lean completely flips that script.

Master techniques like small-batch production and quick equipment changeovers to gain the ability to switch from one product to another without friction. Suddenly, you can react to a new trend, test a bold design, or fulfill a custom order with confidence. For a made-to-order brand like us at Griseo Interior, this agility is our lifeblood. It’s how we bring unique, personalized art and furniture to life for each customer, efficiently and beautifully.

Navigating the Bumps in the Road on Your Lean Journey

Embarking on a lean journey is rewarding, but it's not always a straight line. Knowing the common challenges is the best way to sidestep them and ensure your efforts pay off.

One of the classic mistakes is focusing only on tools—like Kanban boards or 5S checklists—while forgetting about the people. Lean is a human endeavor. If your team isn't bought into the why behind the change, the best tools in the world will just gather dust.

Another momentum-killer is a lack of real leadership support. Leaders must visibly champion the shift, clear roadblocks, and celebrate wins. Your team needs to see that this is a true priority, not just another flavor-of-the-month project.

Start Small, Win Big, and Build from There

Trying to achieve perfection overnight is a surefire way to get discouraged. A real lean transformation is built on a series of small, steady wins. Don't try to overhaul everything at once. Instead, pick your first battle wisely with a focused pilot project.

Zero in on a single, manageable part of your process where you know there’s a problem to solve. This gives your team a safe space to learn, experiment, and see for themselves how powerful these principles are in action.

"A lean transformation is a marathon, not a sprint. Celebrate every small victory along the way. These early wins are the fuel that powers long-term cultural change and builds unstoppable momentum."

When you nail that first project, make some noise about it! Share the results, give credit where it’s due, and use that success story to get everyone else fired up for what's next. This is how you turn skepticism into genuine belief and lay the groundwork for a culture that never stops improving. By taking this steady, thoughtful approach, the benefits of lean manufacturing stop being abstract ideas and become the daily reality of your business, setting you up for incredible, sustainable growth.

Your Questions on Lean, Answered

As you start to see how lean principles could reshape your work, some practical questions are bound to pop up. Let's tackle some of the most common ones that come up when you begin to turn these powerful ideas into reality.

How Long Does It Take to See Results?

While a full cultural transformation is a journey, you can see tangible wins much faster than you might think.

Start small. Pick one workstation and apply the 5S methodology (Sort, Set in Order, Shine, Standardize, Sustain). Map out a single value stream to identify a bottleneck. By focusing your efforts on a specific pilot project, you can achieve measurable improvements in a matter of weeks. These early victories—like a 10-15% reduction in setup time for one task—build the momentum you need to keep going.

Can Lean Really Work for a Small Business?

Absolutely. In fact, small businesses and artisan workshops are often where lean principles shine brightest. Without layers of bureaucracy, small teams can implement changes, experiment with new workflows, and see the results almost instantly.

The core ideas—eliminating waste, creating smooth flow, and focusing on customer value—are universal. A small furniture maker can apply lean by setting up a dedicated finishing station to cut down on wasted movement. A design studio can create a simple pull system for ordering materials. Lean's power isn’t tied to company size; it’s about a commitment to getting better every single day.

Lean isn't about turning your workshop into a massive, impersonal factory. It's about making your unique operation the absolute best it can be. For small, design-driven businesses, this means more time for creativity and less time putting out operational fires.

Is This Just for Manufacturing?

Not at all. The philosophy has broken out of the factory and found a home in countless industries. At its heart, lean thinking can be applied to any process with steps designed to deliver value to a customer.

We've seen it work wonders in healthcare to improve patient flow, in software development to get products to market faster, and even in offices to cut through mountains of paperwork. The mission is always the same: find the activities that don't add value and eliminate them.

At Griseo Interior, we don’t just talk about these principles—we live them. Our made-to-order model is lean thinking in its purest form. We eliminate the waste of overproduction to ensure every single piece is crafted with intention, specifically for you.

See the beauty of mindful production for yourself. Explore our collection and discover the difference.