A Practical Guide to Sustainable Manufacturing Practices

For years, the story was that industry and nature were at odds—that for one to thrive, the other had to suffer. Sustainable manufacturing rewrites that narrative. It's a strategic shift to smarter, more efficient processes that are not only good for the bottom line but also actively protect our planet.

This isn't about compromise. It’s about creating a future where business success and environmental health are two sides of the same coin. This guide provides actionable advice to make that a reality for your business.

The Dawn of a Greener Industrial Age

Welcome to the next industrial revolution—one defined by responsibility, not just raw output. The old, linear model of "take, make, waste" is a dead end. To build a stronger, more resilient economy, you must design waste out of your system from the very beginning.

Think of it like tending a garden instead of running a factory assembly line. In a garden, every element has a purpose, and nothing is wasted; it's a circular, self-sustaining system. That's the heart of sustainable manufacturing: creating a production ecosystem where every resource is valued, and efficiency and ingenuity drive success. This isn't just a feel-good trend; it's the smartest way to do business.

A Movement Gaining Momentum

This shift isn't just a quiet whisper; it's a roar. Driven by consumers who demand better and leaders who see the opportunity, sustainable practices are becoming the new standard. The numbers tell a compelling story.

The global sustainable manufacturing market is projected to reach USD 601.17 billion by 2034, expanding at a compound annual growth rate of 11.1%. This isn't a small, niche market anymore—it’s a massive, sustained investment in a better way of building our world.

This incredible growth proves that sustainable manufacturing is here to stay. It's already reshaping entire industries, from the materials we source to the products on our shelves. You can dive deeper into these trends by exploring the latest sustainable manufacturing market research.

More Than Just a Buzzword

So, what does this actually look like on the factory floor? It’s a series of intentional, practical changes that make a real difference. At its core, sustainable manufacturing is built on actionable strategies like these:

- Smarter Resource Management: Deliberately track and optimize every drop of water, every watt of energy, and every piece of raw material. The goal is to do more with less.

- Waste Elimination: Shift toward a circular economy where one process's "waste" becomes another's raw material. Design systems where nothing is thrown away.

- Clean Energy Adoption: Switch to renewable energy sources like solar and wind to power operations, dramatically cutting your company's carbon footprint.

- Ethical Supply Chains: Partner with suppliers and distributors who share your commitment to high environmental and social standards, ensuring integrity from start to finish.

When you weave these principles into your business, you're not just checking a box. You're building an enterprise that's more efficient, more respected, and truly built to last.

Why Sustainable Manufacturing Is a Business Imperative

Let's be clear: the old idea that "going green" is a burden on the bottom line is completely outdated. For a long time, business leaders saw sustainability as a cost center. That’s no longer the case.

Today, smart companies see sustainable manufacturing for what it truly is: a powerful strategic advantage. It’s a direct path to building a more resilient, efficient, and profitable business for the long haul. This isn't about sacrificing growth for the planet—it’s about recognizing that the two are fundamentally linked.

Slashing Costs Through Efficiency

At its heart, waste is just a symptom of inefficiency. Every bit of discarded material, every watt of wasted electricity, and every oversized shipment is money slipping through the cracks. Sustainable manufacturing provides a framework to tackle these inefficiencies head-on, transforming them into serious savings.

Think about it like a leaky faucet. A single drip might not seem like much, but over a year, it adds up. Now, apply that to a factory scale. By finding and fixing those operational "leaks," you can unlock immediate and substantial financial gains.

This is a proven strategy. The data shows that a focus on sustainability can slash operational costs by as much as 20%. It’s no wonder that 70% of manufacturers now treat sustainability as a critical factor when choosing their partners. You can find more fascinating insights into these manufacturing statistics on e-bi.com.

Building a Brand Customers Trust

Today’s customers are savvier than ever. They don't just buy products; they buy into brands that reflect their own values. A genuine commitment to sustainability has become a major driver of customer loyalty.

When you're transparent about your sustainable journey, you build a powerful bond with your audience. This creates an emotional connection and a competitive edge that goes far beyond a simple price comparison.

When customers see that a brand is truly dedicated to ethical sourcing, low-waste production, and environmental care, they don’t just become satisfied—they become advocates. That kind of positive reputation is one of the most valuable assets you can possibly build.

This loyalty pays off. People actively seek out responsible brands and are willing to put their money where their values are. A global survey revealed that a staggering 66% of consumers would pay more for a product from a sustainable brand. Among millennials, that number climbs even higher to 73%.

The Strategic Business Case for Sustainability

The evidence is overwhelming: sustainable manufacturing delivers a one-two punch that's impossible to ignore. On one side, you create leaner, more cost-effective operations. On the other, you build a brand that truly resonates with the modern consumer.

Let's break down how these benefits really stack up.

The Business Case for Sustainable Practices

This table neatly summarizes the powerful economic and reputational returns that come from embedding sustainable practices into your manufacturing.

| Benefit Area | Description | Supporting Statistic |

|---|---|---|

| Operational Savings | Reduces expenses related to energy, water, and raw materials through hyper-efficient processes. | Businesses report an average of 34% cost savings from supply chain sustainability initiatives. |

| Increased Revenue | Attracts and retains environmentally conscious customers, opening new market segments. | Up to 40% of companies have seen direct revenue growth from their sustainability investments. |

| Enhanced Reputation | Builds trust and loyalty by demonstrating a strong commitment to ethical and environmental values. | 66% of global consumers are willing to pay more for sustainable goods, strengthening brand equity. |

| Future-Proofing | Improves resilience against resource scarcity and tightening environmental regulations. | Proactive adoption positions a company to lead, not just react, in a rapidly changing global market. |

Ultimately, by embracing sustainability, you're doing more than just making a positive impact on the world. You're making a brilliant business move that secures your company’s long-term success and relevance. It's an investment in efficiency, reputation, and a brighter future for everyone.

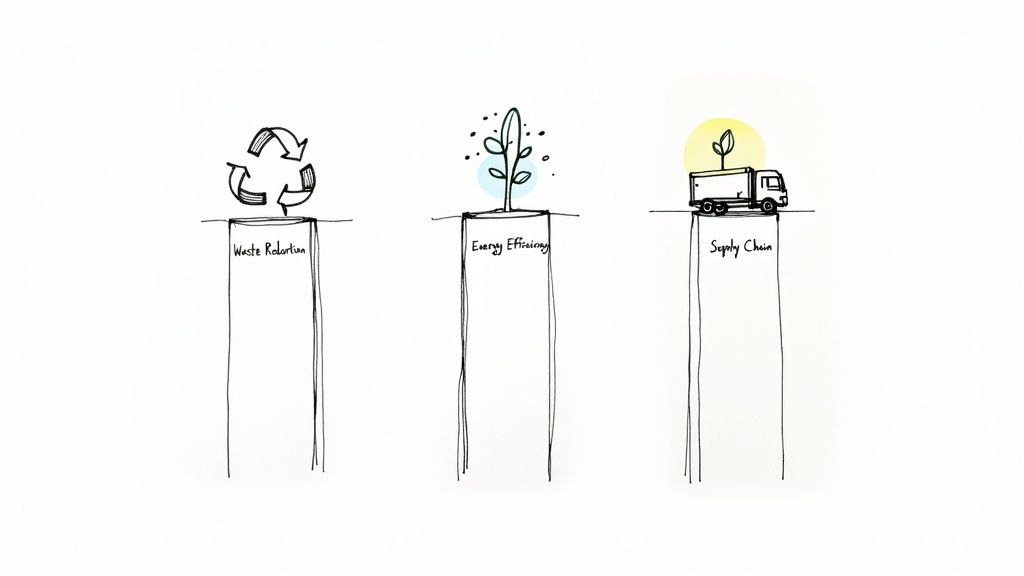

The Three Pillars of Sustainable Production

Implementing sustainable manufacturing can seem complex, but it boils down to three powerful, interconnected pillars. By focusing your efforts on these core principles, you can lay the groundwork for real, lasting change.

View these pillars not as a checklist, but as the foundation of a stronger, more resilient business. Each one reinforces the others, creating a company that’s more efficient, innovative, and perfectly in tune with what today's customers value. Let's break this down into actionable pieces you can start using right away.

Pillar One: Waste Reduction and the Circular Economy

Think about a forest floor. When a leaf falls, it isn't "waste." It becomes food for the soil, nourishing new growth. That's the essence of the circular economy—a system designed to eliminate waste by keeping resources in use.

The standard industrial model has been linear: take, make, dispose. The circular model challenges you to see every output as a potential input for something else.

The goal is to create a closed-loop system where materials are endlessly recycled, remanufactured, or repurposed. This simple shift in perspective turns a cost center—waste management—into a source of value and innovation.

Here's how to bring this to life in your operations:

- Design for Disassembly: Build products so they can be easily taken apart at their end of life. This makes it simple to recover valuable materials and components for reuse.

- Embrace Remanufacturing: Take older or returned products, restore them to like-new condition, and bring them back to the market. This saves the significant energy and raw materials required to make a new product from scratch.

- Start a "Waste-to-Resource" Program: Conduct a thorough audit of your production line. Identify every byproduct and ask, "How could this be used?" You may find an internal use or a partner business that can use your "waste" as their raw material.

Pillar Two: Energy Efficiency and Renewable Sources

Every facility uses energy, but how it's produced and managed makes all the difference. This pillar focuses on two key actions: using less energy and switching to clean, renewable sources. It’s one of the fastest ways to slash both your operating costs and your environmental footprint.

First, plug the energy leaks in your current system. It’s amazing how much energy is wasted through old machinery, poor insulation, or equipment left running when not in use. Once you’ve optimized your usage, you can explore cleaner power sources.

Actionable Steps for Energy Transformation

- Conduct an Energy Audit: Hire an expert or use IoT sensors to map exactly where your energy is going. This will quickly identify the biggest drains and highlight easy opportunities for improvement.

- Upgrade Your Equipment: Replace outdated motors, lights, and HVAC systems with modern, high-efficiency models. The upfront investment is often paid back quickly through lower utility bills.

- Explore On-Site Generation: Investigate installing renewable energy sources at your facility, like solar panels. This can lower your carbon footprint, provide more predictable energy costs, and increase independence from the grid.

- Optimize Your Schedules: Run your most energy-intensive machines during off-peak hours when electricity is cheaper. This smart scheduling can lead to significant savings without any new equipment.

Pillar Three: Supply Chain Responsibility

A manufacturer’s responsibility doesn’t stop at the factory doors. This pillar extends the ideals of sustainability to your entire supply chain—from raw material sourcing to final product delivery. A truly sustainable company ensures its partners are equally committed to high ethical and environmental standards.

This means looking beyond price and delivery time when choosing suppliers. For instance, when sourcing a material like wood, it's crucial to partner with suppliers who practice responsible forestry. You can see what makes a material like solid acacia wood a great sustainable option in our detailed guide.

A responsible supply chain is also a more resilient one. By building a network of ethical suppliers and sourcing locally when possible, companies can better navigate global disruptions and build a brand story that customers trust.

A global survey found that a staggering 66% of consumers are willing to pay more for products from brands that show they care about social and environmental issues. Your supply chain isn't just a line item; it's a powerful story you tell your customers.

To build a more responsible supply chain, start with these actions:

- Create a Supplier Code of Conduct: Document and enforce a clear set of environmental, social, and ethical expectations for every partner you work with.

- Prioritize Local Sourcing: Whenever feasible, choose local suppliers. This reduces shipping emissions and invests money back into your community.

- Optimize Your Logistics: Use route-planning software to make deliveries more efficient. Consolidate shipments and partner with carriers investing in electric vehicles and other green technologies.

By weaving these three pillars—waste reduction, energy efficiency, and supply chain responsibility—into the fabric of your business, you create a powerful, integrated strategy. This is the blueprint for building a company that is not only profitable but also a true force for good in the world.

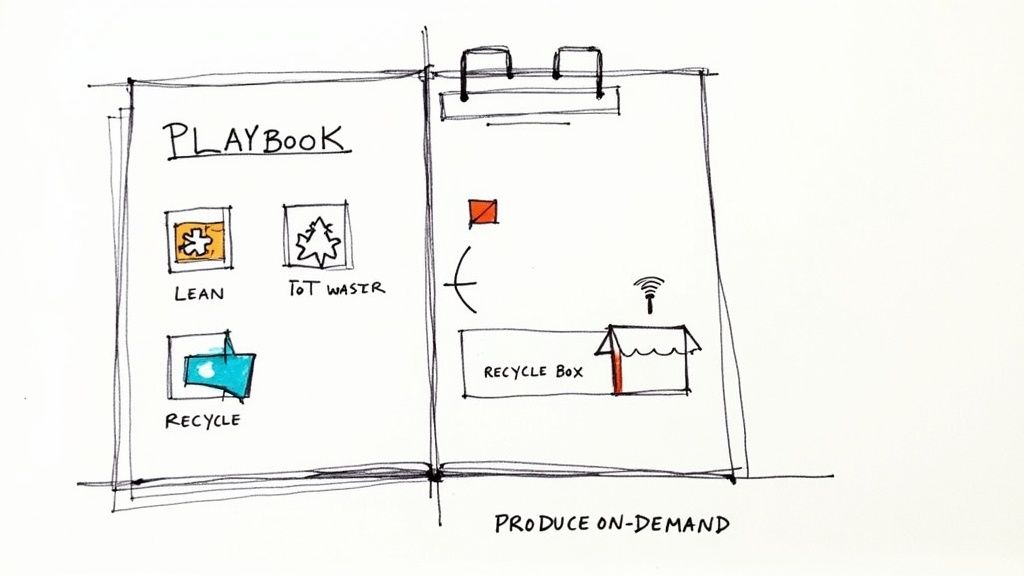

Your Playbook for Sustainable Implementation

Knowing the principles is one thing; putting them into motion is where real change begins. This is your practical playbook—a collection of proven strategies to reshape your operations. These are actionable steps you can start taking today, no matter the size of your business.

The path to sustainable manufacturing isn’t a single leap. It’s a series of smart, deliberate choices that build on one another. By focusing on these tangible improvements, you can start building a more efficient, responsible, and future-ready business right now.

Adopt Lean Manufacturing Principles

At its core, lean manufacturing is the art of creating more value with less waste. This philosophy aligns perfectly with sustainability because every scrap of material, wasted minute, and unnecessary motion is a cost to both your bottom line and the planet.

A lean manufacturer analyzes their entire production line with a sharp eye, constantly asking, "How can we do this better, with less?"

By embracing lean principles, you're not just trimming fat; you're fundamentally redesigning your processes to be inherently more sustainable. This approach proves that ecological responsibility and peak operational efficiency are two sides of the same coin.

Here’s how you can get started:

- Conduct a Waste Audit: Walk your production floor and map every step. Pinpoint where materials are discarded, where energy is being wasted, and where processes are hitting bottlenecks.

- Streamline Workflows: Organize workstations to reduce unnecessary movement of people and materials. A logical flow saves time, conserves energy, and boosts morale.

- Empower Your Team: Your people on the ground are your greatest asset. Train them to spot inefficiencies and encourage them to suggest improvements.

Integrate Smart Technology for Real-Time Monitoring

You can't fix what you can't see. Integrating Internet of Things (IoT) sensors into your machinery gives you a powerful, real-time view of your resource consumption. It’s like giving your factory a nervous system that tells you exactly where you're using too much energy or water.

These intelligent sensors can be attached to motors, lighting, and water lines to track usage second by second. The data delivers immediate, actionable insights. For example, a sensor might reveal a machine is drawing power when idle, prompting a simple change in shutdown procedures that saves thousands. This technology helps you shift from guesswork to data-driven decisions, unlocking new levels of efficiency. It's a critical tool in modern sustainable manufacturing practices.

Champion the Produce-On-Demand Model

One of the biggest culprits of waste in traditional manufacturing is overproduction. Companies often produce goods based on forecasts, leading to unsold inventory that takes up space and eventually ends up in a landfill.

The produce-on-demand model flips that script.

This approach, central to our philosophy at Griseo Interior, means a product is only created after a customer places an order. It's a direct response to a real need, eliminating the guesswork and waste of mass production. This method is a cornerstone of eco-friendly interior design, ensuring that precious resources are only used to create something truly wanted.

The On-Demand Advantage: A Look at Griseo Interior

- No Overproduction: By crafting each piece for a specific customer, we completely eliminate the risk of unsold stock. That means no wasted materials, energy, or labor on products that no one asked for.

- Reduced Storage Footprint: Warehousing inventory burns energy for lighting and climate control. Our on-demand model requires minimal storage, shrinking our environmental footprint.

- Greater Customization: This model fosters a deeper connection with our customers, as each item is made with them in mind. It turns manufacturing from a faceless process into a personal, artisanal craft.

Making this shift takes a new way of thinking, but the payoff in waste reduction and resource conservation is immense.

Implement a Robust Recycling Program

Finally, close the loop on your materials. An effective recycling program goes far beyond placing a few bins around the building. It’s a systematic approach to segregating, collecting, and repurposing every possible material.

Start by identifying all of your waste streams, from office paper and plastics to industrial scrap metals and chemicals. Then, partner with specialized recycling firms that can help you turn that "waste" back into valuable raw materials. The ultimate goal is to send as little as possible to the landfill, moving closer to a circular model where every resource is respected and kept in use.

Innovations Powering the Green Revolution

The idea of a factory running with near-perfect precision, almost no waste, and peak efficiency isn't a futuristic dream. It’s happening right now, thanks to technologies making sustainable manufacturing practices more accessible than ever. These aren't just minor tweaks; they're the tools turning ambitious green goals into everyday reality.

This is about a complete rethink of how we make things, driven by data, smart automation, and intelligent systems. Technology is what's giving us the ability to build smarter, cleaner, and far more responsibly.

Perfecting Production with Digital Twins

Imagine building your entire factory in a virtual sandbox, running it at full tilt before ordering a single machine. That’s the power of a digital twin—a living, virtual replica of a physical asset or process. It’s one of the most exciting developments in modern manufacturing.

Instead of relying on expensive and wasteful physical trial-and-error, companies can use these simulations to test production lines, fine-tune workflows, and predict maintenance needs. A digital twin lets you iron out every wrinkle in a risk-free digital world, saving huge amounts of time, energy, and materials.

This technology is quickly becoming the bedrock of sustainable production. It gives businesses the power to perfect their operations in a virtual space, ensuring that when the real-world factory goes live, it runs with incredible efficiency and minimal environmental impact from day one.

The industry is catching on. Research is booming, with over 640 patents and more than 410 grants expected in this space in 2025 alone. By 2030, an estimated 70% of manufacturers will be using digital twins, cutting development costs by 15% while boosting their operational efficiency. If you're curious, you can discover more about the top trends in sustainable manufacturing to see how these technologies are shaping the future.

The Rise of Smart Factories and IoT

Think of the Internet of Things (IoT) as the central nervous system of a sustainable factory. It’s a network of connected sensors and devices that gather real-time data from every corner of the production floor—from a machine's energy draw to its operating temperature.

This constant flow of information gives you a crystal-clear view of your operations, allowing you to make instant, data-driven decisions that slash waste and improve efficiency.

How to leverage IoT for sustainability:

- Predictive Maintenance: Use sensors to detect when a machine is about to fail, so you can schedule repairs before it breaks down. This prevents costly downtime and energy-intensive emergency fixes.

- Energy Optimization: Implement IoT systems to monitor lighting, heating, and machinery in real time, automatically dimming lights or powering down equipment to use the minimum energy needed.

- Resource Tracking: Install smart sensors to monitor the flow of raw materials and water, instantly spotting leaks or bottlenecks that lead to waste.

Additive Manufacturing and the Zero-Waste Ideal

Another game-changer is additive manufacturing, commonly known as 3D printing. Traditional "subtractive" manufacturing is like sculpting—you start with a block of material and cut away everything you don't need, creating waste. 3D printing does the opposite. It builds objects layer by layer, using only the precise amount of material required.

This method is the heart of the on-demand production model, making it a natural fit for a zero-waste philosophy. It's what allows a company like Griseo Interior to create beautiful, intricate items with almost no leftover material, turning a digital design file directly into a physical product. You can explore our guide on how 3D-printed home decor is pushing the industry in a better direction. This approach completely redefines what’s possible, merging incredible design freedom with profound respect for our resources.

Charting Your Sustainable Course

If there's one powerful truth to take away, it's this: what's good for our planet is fantastic for business. We've moved past "why" and delved deep into the "how," providing a path where smart efficiency, genuine innovation, and a strong sense of responsibility meet. This is about more than shrinking a carbon footprint; it's about building a more intelligent, resilient, and future-proof company.

When you embrace this way of thinking, you see waste as a resource, energy use as a strategic lever, and supply chains as networks built on trust. The results are real. You see it in the significant savings on operational costs and feel it in the deep loyalty you earn from customers who know you’re committed to doing the right thing. It's a profound shift away from the old take-make-dispose model and toward a circular approach where every material matters and every action is intentional.

Your business isn't just a bystander in this global shift; it's a leader in the making. Every single step you take—whether it's embracing on-demand production or investing in cleaner technology—helps shape a more responsible and enduring industrial future.

The time for bold, decisive action is now. You have the playbook in front of you, filled with practical strategies and proven methods ready to be put into action. This is your invitation to lead from the front, innovate with purpose, and build a legacy that extends far beyond the bottom line. The next chapter of industry is being written today, and it’s a story that is inspiringly, and necessarily, sustainable. Let this be your moment to accelerate the journey and claim your place as a leader in the green industrial age.

Got Questions? We’ve Got Answers.

Stepping into the world of sustainable manufacturing can feel like charting new territory. It's only natural to have a few questions. Let's clear up some of the most common ones so you can move forward with confidence.

What’s the Biggest Hurdle to Getting Started?

The biggest hurdle is often the perceived upfront cost. Many business leaders get stuck on the initial investment for new, greener technology and hesitate. They see a large number and worry about the immediate hit to the bottom line.

However, many of these changes pay for themselves surprisingly fast by slashing day-to-day operational costs. The trick is to start small. Don't try to overhaul everything at once. Kick things off with low-cost, high-impact changes, like a simple waste audit or optimizing equipment schedules. These early wins build momentum and prove the financial value, making it much easier to get approval for bigger projects later on.

How Can a Small Business Even Begin to Do This?

For small businesses, sustainability is more about process than expensive technology. It's about being smarter with what you already have. Adopting lean manufacturing principles, for example, is all about cutting out waste and doesn't require a huge capital investment.

It really comes down to being resourceful and intentional. Smart, steady changes add up to a massive impact over time. A smaller budget doesn't mean you can't be a powerful force for good.

Here are a few practical ideas to get you started:

- Source Locally: Find suppliers in your area who share your values. You'll cut down on shipping emissions and support your local economy at the same time.

- Get Your Team on Board: Your employees can be your biggest allies. Start simple energy-saving challenges, like making sure all equipment is powered down at the end of the day. You’d be amazed at how much those small habits save.

- Level Up Your Recycling: Go beyond just putting out a blue bin. Create a dedicated system for separating and recycling every possible material.

How Do You Actually Measure the ROI on This Stuff?

Measuring the return on your sustainable manufacturing practices requires looking at both hard numbers and softer benefits. The financial wins are the easiest to track and are essential for building a solid business case.

Start by tracking direct cost savings from reduced consumption:

- Energy: Monitor your utility bills to see the direct impact of your efficiency upgrades.

- Water: Track your water usage to quantify how much your conservation efforts are saving.

- Raw Materials: Measure the reduction in raw material purchases as a result of smarter processes and less waste.

But don't stop there. The less tangible returns are where the long-term value lies. Track metrics like customer acquisition cost, brand sentiment online, and employee turnover. These numbers help tell the story of how sustainability is strengthening your brand, earning you fiercely loyal customers, and creating a happier, more committed team.

At Griseo Interior, we believe that true beauty is born from responsible creation. Our on-demand model ensures every piece is made with purpose, eliminating waste and honoring the resources we use. Discover home décor that blends timeless Italian design with a commitment to a healthier planet. Explore the collection at griseointerior.com.