Exploring the Core Additive Manufacturing Benefits

To leverage additive manufacturing effectively, you need to understand its core strengths: unprecedented design freedom, on-demand hyper-customization, and a drastically smaller environmental footprint. The technology works by building objects layer by layer from a digital file, completely sidestepping the old rules of traditional manufacturing. Start thinking about how you can use this process to create products that are complex, lightweight, and deeply personal.

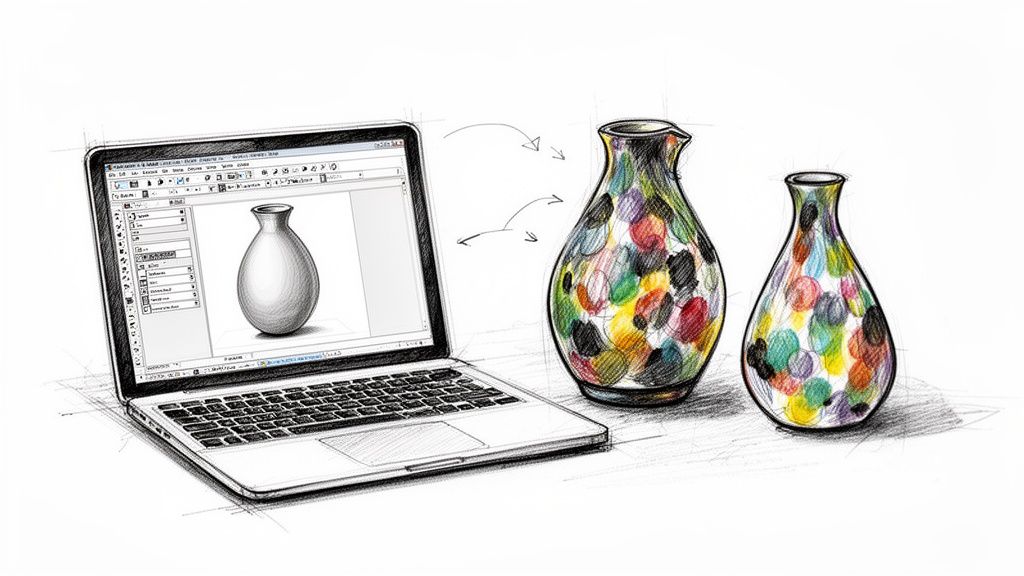

From Imagination to Tangible Reality

Imagine holding an object that, just a few hours ago, was only an idea on your screen. To make this happen, you must grasp how additive manufacturing turns digital blueprints into physical reality with breathtaking precision.

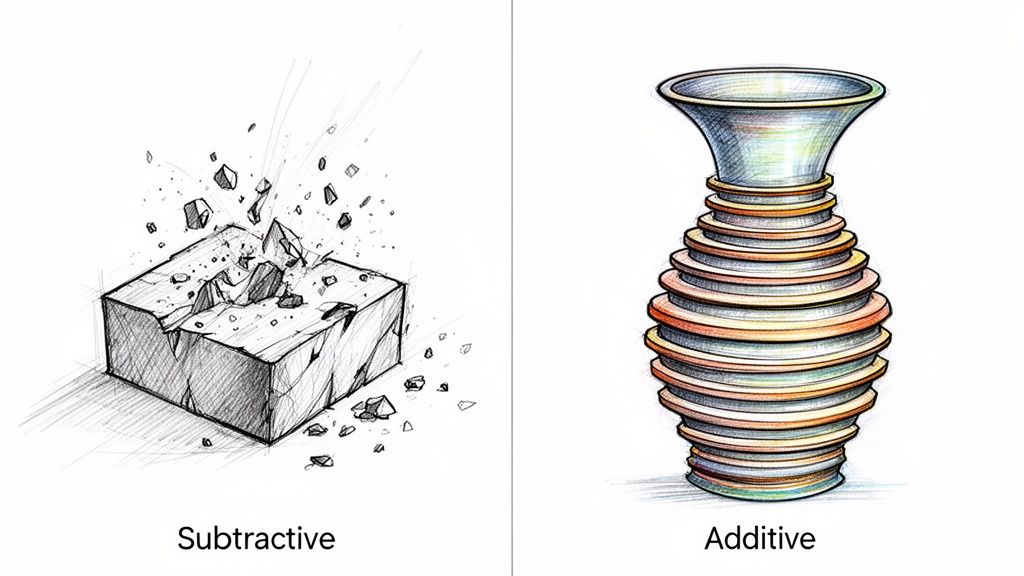

Traditional methods are subtractive; you start with a block of material and carve away what you don't need. To take advantage of 3D printing, you must flip that script. It's additive, so you design by meticulously building objects one layer at a time, using only the exact amount of material required. Treat it like sculpting with digital clay, where you can ignore the typical constraints of molds and machinery.

Unlocking Boundless Design Freedom

This layer-by-layer method is a game-changer for what's possible. To fully benefit, free your designs from the straight lines and simple shapes that conventional molding and milling demand. This is your chance to bring to life forms that were once considered impossible or too expensive to attempt.

To maximize this freedom, start incorporating these techniques into your designs:

- Design Intricate Internal Structures: Actively design objects with complex internal lattices. This will make them incredibly strong yet surprisingly lightweight—a key strategy used by aerospace and medical industries for critical parts.

- Embrace Organic and Fluid Shapes: Create graceful curves and flowing, nature-inspired forms with perfect accuracy. You no longer need complicated multi-part molds, so design accordingly.

- Consolidate Components: Redesign assemblies of multiple separate parts so they can be printed as a single, seamless piece. This action boosts structural integrity and simplifies your entire production process.

To get the most from additive manufacturing, use it as a direct bridge from imagination to creation. Focus your efforts on the ideal form and function of an object, rather than compromising your vision to fit the constraints of old-world manufacturing.

Engineering Beauty with Purpose

This is about more than aesthetics; it's a call to engineer better, smarter products. At Griseo Interior, we apply this design freedom to our collections. You can see the results in our Prisma and Serenitatem vases, with their complex geometries and sharp, crystalline forms—achievements that would be impossible with traditional ceramic or glass molding.

To translate a pure design vision into a physical product, use this process to create pieces that are not just visually stunning but also structurally sound and utterly unique. It provides a more direct, unfiltered connection between the artist’s intent and the final piece.

Grasping this idea is the first step. To see just how deep this goes, learn more about how 3D printing is reshaping modern design in our detailed guide. Start applying this fusion of art and engineering to define the next generation of decor and turn everyday objects into functional sculptures.

Crafting Objects That Tell Your Story

In a world of mass production, offer something made just for your customer. Deliver an object that reflects their taste, fits their space perfectly, and feels uniquely theirs. Use additive manufacturing to bring this personal connection back to the forefront by treating every single creation as its own distinct project.

Traditional manufacturing is rigid; it’s built around expensive, unchangeable molds. To innovate, leverage 3D printing's digital file foundation. Changing a design becomes as easy as editing that file—a process of minutes, not months. Capitalize on this inherent flexibility, one of the most incredible additive manufacturing benefits, to turn production into a living conversation with your customer.

The Freedom of Digital Creation

Think about the last time you found an object you loved but wished it was just a little different. With additive manufacturing, you can make those “what ifs” a reality for your clients.

Since you are working from a digital blueprint, you can collaborate with customers to make adjustments that tell their story. Here's how to put this into practice:

- Offer Perfect Proportions: Provide the service of scaling a piece like our Stoic vase to feel completely at home in any space, creating a sense of balance and intention.

- Enable Detail Refinements: Let customers subtly alter intricate patterns and surface textures in the digital model. This adds a layer of personalization that’s impossible with older methods.

- Make It Truly Theirs: Go even further by offering services like embedding a monogram or creating an entirely new form from scratch. Use the technology to craft a genuine one-of-a-kind object.

This capability moves an object beyond being a simple product. It becomes a personal statement. For us, it’s a direct line from our design studio in Vigonza to your living room, creating a much deeper relationship with the things you surround yourself with.

To create a premium experience, offer hyper-personalized objects. It’s the difference between buying a suit and having one tailored—the fit, the feel, and the connection are on an entirely different level.

Bringing Bespoke Design Within Reach

Not long ago, this kind of customization was reserved for elite artisans. But as the technology evolves, you can make on-demand creation a practical reality for your own studio.

The global additive manufacturing market is booming, expected to grow significantly from its USD 23–25 billion valuation in 2024. As the technology becomes more widespread, the machinery and materials become more accessible. You must leverage this to lower the cost of producing small batches—or even just one. This shift is everything for a made-to-order decor studio. Dive deeper into this growth with Research and Markets' latest report.

For us at Griseo Interior, this means we can create a single, beautiful object just for you, without the economic pressures of mass production. Implement a similar model to ensure every piece is brought to life for the person who will cherish it, honoring the simple joy of owning something made with them in mind.

A Better, More Sustainable Way to Create

True luxury today demands responsibility. To meet this expectation, leverage one of the most powerful additive manufacturing benefits: its natural alignment with conscious creation.

Think about it like this: traditional manufacturing is like carving a statue from a massive block of stone. The final form is beautiful, but it wastes all the discarded chips on the floor.

To be more sustainable, adopt an additive approach. It's like building a sandcastle, placing each grain of sand exactly where it needs to be. Nothing is wasted. This simple shift—building up instead of cutting away—should be at the heart of your process. It's how we at Griseo Interior honor our planet’s resources while bringing beautiful, bespoke objects into the world.

Saying Goodbye to Overproduction and Waste

The old manufacturing model runs on guesswork. Companies produce thousands of items, hoping they’ll sell. Often, they don't, leading to warehouses of unsold goods that end up in landfills.

To fix this broken model, switch to additive manufacturing. Only create an object when a customer orders it. This simple, direct approach eliminates the enormous environmental cost of overproduction. Your action ensures every bit of material has a purpose.

Adopt an on-demand model as more than a business strategy; make it a promise. Ensure no material is used, no energy is spent, and no object is brought into the world without a home eagerly waiting for it.

Traditional vs. Additive Manufacturing A Sustainability Comparison

When you dig into the details, the contrast between old and new production methods becomes incredibly stark. The table below shows you how to achieve better environmental outcomes, highlighting why we believe additive manufacturing is the future.

| Factor | Traditional (Subtractive) Manufacturing | Actionable Strategy with Additive Manufacturing |

|---|---|---|

| Material Use | High waste; material is cut away from a larger block, creating significant scrap. | Minimize waste by building objects layer by layer, using only the necessary material. |

| Inventory | Large stockpiles of unsold goods require extensive warehousing and energy. | Eliminate physical inventory by maintaining a "digital warehouse" of files to achieve zero overproduction. |

| Tooling | Requires expensive, permanent molds and tools that have a limited lifespan. | Remove the need for physical tooling; keep designs digital to reduce material and energy costs. |

| Supply Chain | Long, complex global chains with high transportation emissions. | Implement localized production to reduce shipping distances and the associated carbon footprint. |

This move toward smarter, on-demand production isn't just a niche idea; it's a full-blown movement. In 2023 alone, polymer-based 3D printing methods produced over 11.1 million parts, and the total number of consumer product parts soared to nearly 37 million—a 23% jump from the year before. The numbers tell a clear story: you should embrace a model where reducing waste is a top priority.

This conscious mindset is weaving its way into every corner of our lives. You can see it in brands offering everything from thoughtfully made home goods to sustainable sleep solutions. Use your brand to empower customers to make choices that feel right.

Our approach at Griseo Interior is proud to be part of this larger shift. To see how deeply this philosophy runs, review our guide to sustainable manufacturing practices and discover how you can shape a better future.

Creating a Radically Efficient Supply Chain

Think about the journey most products take: it's long, fragile, and inefficient. To fix this, you need a more direct and intelligent path forward. Use additive manufacturing to simplify this tangled web and build a supply chain that's more resilient, agile, faster, and far kinder to our planet.

The Power of a Digital Warehouse

Imagine a warehouse with infinite shelf space that takes up zero physical room. Your first step is to create a digital warehouse, a core benefit of 3D printing that reimagines inventory.

Instead of filling shelves with physical products, maintain a library of digital designs. These files are pure potential, ready to be brought to life anywhere, anytime, but only when they're actually needed.

Implement this for immediate and profound advantages:

- Eliminate Physical Storage Costs: Do away with the need for vast, energy-hungry warehouses filled with unsold goods.

- Enable Instant Design Updates: When you refine a design, simply update a single digital file. There’s no outdated physical stock to throw away.

- Maintain Infinite 'Stock': A design is never "out of stock." As long as the digital file exists, the object can be created on demand.

A digital warehouse isn't just for storing files; it's a new philosophy. Shift your focus from managing physical objects to managing pure information. This will make your entire system lighter, faster, and infinitely more flexible.

This digital-first approach is how you can serve a global community with the heart and agility of a local studio. From our workshop in Vigonza, Italy, we can send a freshly crafted piece directly to a customer's doorstep, bringing authentic 'Made in Italy' craftsmanship to them without the usual logistical nightmares.

Localized Production for a Global World

This decentralized model has massive implications. To make your global supply chain dramatically more efficient and sustainable, produce objects much closer to where they will be used.

By producing on-demand, you can slash transportation emissions, shipping delays, and the complicated costs of global logistics. Research shows this localized approach helps get things where they need to be faster and keeps operations running smoothly. For a deeper dive into how this agile model works, our guide to sustainable supply chain practices explores these ideas in more detail.

At Griseo Interior, this means we don't ship a container full of vases across the world. Instead, we create your specific piece only after you’ve ordered it. You can do the same. This not only cuts down the carbon footprint of long-haul freight but also ensures that the object your customer receives was made with intention, specifically for their space.

Adopt this system to honor both timeless craftsmanship and modern efficiency, delivering beauty faster and more responsibly than ever before.

Balancing Modern Speed with Timeless Craftsmanship

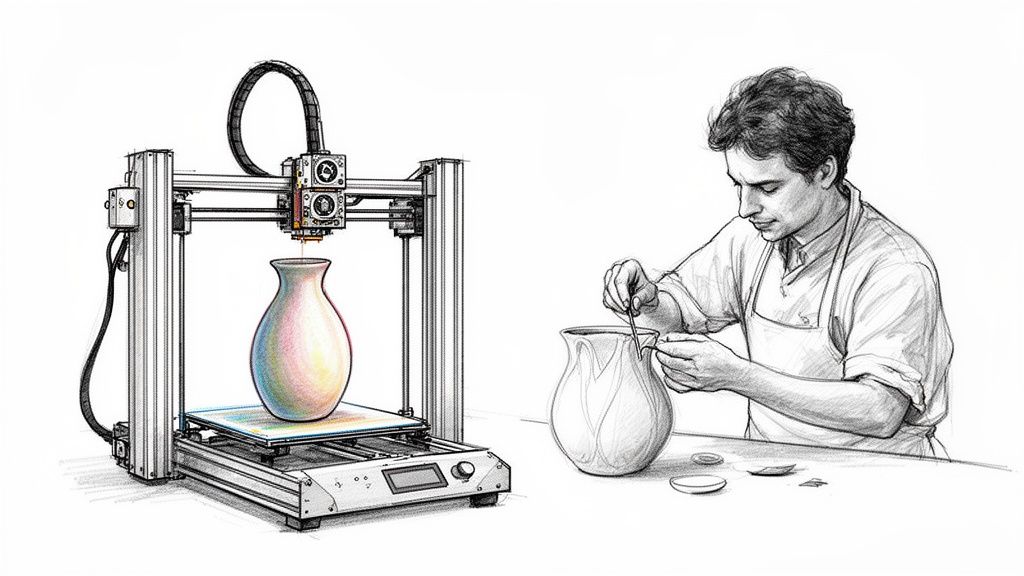

When people hear "3D printing," they often picture instant creation. And while additive manufacturing can produce a single, complex object faster than tooling an assembly line, its real power in artisanal production isn't sheer speed. To succeed, focus on deliberate, thoughtful creation.

The process is anything but instantaneous. Every piece we create, whether a minimalist vase or an intricate sculpture like the Leo Ales Venetian Winged Lion, undergoes a two-part journey. It starts with methodical, layer-by-layer construction. But that’s only the beginning.

The real soul of the object emerges when skilled artisans take over for meticulous hand-finishing. To create truly exceptional products, you must marry advanced technology with the irreplaceable human touch. This is what defines our work at Griseo Interior.

Quality as a Measure of Time

Be upfront about your lead times because they reflect a core value: a commitment to quality over immediacy. In a world obsessed with next-day delivery, you should align with the principles of the 'slow design' movement. This philosophy champions intentionality, longevity, and a deeper connection to the objects we choose to live with.

Build your process on this foundation. Here’s how you can balance modern methods with timeless care:

- Use Precision Printing: The initial 3D printing can take many hours, sometimes even days. This careful pace is what guarantees perfect form and structural integrity, so don't rush it.

- Invest in Artisanal Finishing: Once printed, ensure every object is painstakingly sanded, smoothed, and finished by hand. This crucial step removes any trace of the printing process and imparts a unique, tactile quality a machine cannot replicate.

- Implement Rigorous Inspection: Before a piece is ready for its new home, perform a final quality check to ensure it meets your exacting standards for beauty and durability.

The time you invest in each object isn’t a delay; it's a vital part of its creation story. Use this time to let technology’s precision meet the warmth of human craftsmanship, resulting in a piece with character and soul.

The Value of Made-for-You Craftsmanship

This deliberate pace is one of the most misunderstood yet essential additive manufacturing benefits for artisanal decor. Unlike mass production, where speed is the engine of profit, your on-demand model must be driven by intention.

When a customer places an order with Griseo Interior, they are commissioning a piece to be made specifically for them. It wasn't sitting on a warehouse shelf. Its creation story begins with their decision. Replicate this experience by making every step that follows a direct response to your customer's order.

This approach ensures that you honor the materials, the design, and—most importantly—the person who will cherish the piece. The slight wait is a small price to pay for an object that isn’t just manufactured, but truly crafted. Communicate this value clearly: it’s the difference between a product and a possession, a piece of houseware and a future heirloom. This is how you create something with a story, made with purpose.

Where the Future of Design Meets Your Home

All these actionable ideas—from limitless design possibilities to a truly sustainable way of making things—come to life in one place: your home, with a piece from Griseo Interior. This is where theory becomes tangible. It’s a philosophy of creation you can see, touch, and live with every day.

Our collections are born from these very principles. The crisp lines of the Prisma vase? That’s only achievable with the pinpoint precision of building an object layer by layer. The way a Stoic vase can be scaled to fit your exact shelf space? That’s the magic of on-demand customization. Even the graceful form of the Serenitatem vase speaks to a process that uses only what it needs.

A New Way to Think About Your Decor

We want you to see these pieces not just as objects, but as partners in a more thoughtful way of living. When you bring a Griseo Interior piece into your home, you're embracing our mission: to fuse the soul of timeless Italian craftsmanship with the promise of responsible modern technology.

Each object we create is a conversation starter—a story of intentional design, conscious production, and personal expression. It’s an invitation to embrace a new way of living with beautiful things, one that is more mindful, meaningful, and sustainable.

Choosing Griseo is about more than what an object looks like. It's a conscious decision to champion a system that puts craftsmanship before mass production and sustainability before disposability. You're not just buying a vase; you're welcoming a new set of values into your life.

Elevate Your Space with Intention

Come and see for yourself how an object made with true intention can transform a room. A single vase, brought to life from a digital file and meticulously hand-finished in our Vigonza studio, embodies all the additive manufacturing benefits we've explored. It’s a testament to beauty, innovation, and a better way of creating.

Explore our collection and find the piece that feels like it was made just for you. Let it be a daily reminder that the most beautiful things in our lives are the ones that reflect our deepest values, enriching our homes and our world with purpose.

Frequently Asked Questions About Additive Manufacturing

Diving into a new way of creating beautiful objects naturally sparks curiosity. As you think about bringing 3D-printed decor into your home, we want to give you clear, honest answers that leave you feeling excited and confident about your choice.

Is 3D-Printed Décor Durable?

Absolutely. When people hear "plastic," they often picture something flimsy, but the materials we use for high-end additive manufacturing are in a completely different world. We select advanced, high-performance biopolymers specifically for their strength, resilience, and ability to stand the test of time.

These are not your everyday plastics. Think of them more like engineered materials, the same kind trusted in demanding fields like aerospace and automotive design. Once a piece is printed, our artisans get to work, meticulously hand-finishing every detail to strengthen its structure and create a beautiful, lasting surface. The result is an object built to be a treasured part of your home for many years.

Can I Request a Custom Design?

Yes, and this is where the magic really happens. One of the greatest additive manufacturing benefits is the freedom to break away from the one-size-fits-all model and create something that is uniquely yours. We see our process as a collaboration—a partnership between your vision and our craft.

Customization is at the very heart of our philosophy. It turns an object from just another product into a personal statement, a piece that tells your story.

Maybe you need a vase in a very specific size, want to adjust a pattern, or have a completely new form in mind. The digital foundation of our work makes it all possible. This back-and-forth ensures the final piece doesn't just fit your space perfectly but feels like it was always meant to be there.

Why Does a Made-to-Order Piece Take Longer?

A made-to-order object takes a little more time simply because it doesn't exist until you dream it up. Unlike mass-produced items waiting in a warehouse, your piece begins its journey the moment you place your order. This thoughtful, deliberate approach is fundamental to our commitment to both sustainability and quality.

The waiting period is a direct result of two of our core values:

- Zero Waste: By creating only on-demand, we use precisely the materials needed for your specific object. This completely cuts out the waste that comes from overproduction.

- Dedicated Craftsmanship: From the precision of the printing process to the hours of careful hand-finishing that follow, each object gets our team’s undivided attention.

This intentional pace ensures the piece you receive wasn’t just made—it was made with purpose, specifically for you.

Ready to bring a piece of modern Italian craftsmanship into your home? Explore the full collection at Griseo Interior and discover decor that blends timeless design with a forward-thinking, sustainable vision. Find your perfect piece at https://griseointerior.com.